ABOUT the Sani-Slat

Sani-Slat DesigN

The Sani-Slat was designed by companies who have sold and installed many other slats on the market. We have come up with a premium product, with special design features that include: Hygiene, Strength, and Ease of Installation. These features help set the Sani-Slat apart from other slats.

The Sani-Slat flooring system is manufactured of high quality 100% virgin plastic materials produced in the USA. They can be used to replace wood slats in both Layer and Breeder Houses. They offer a longer life than other slats.

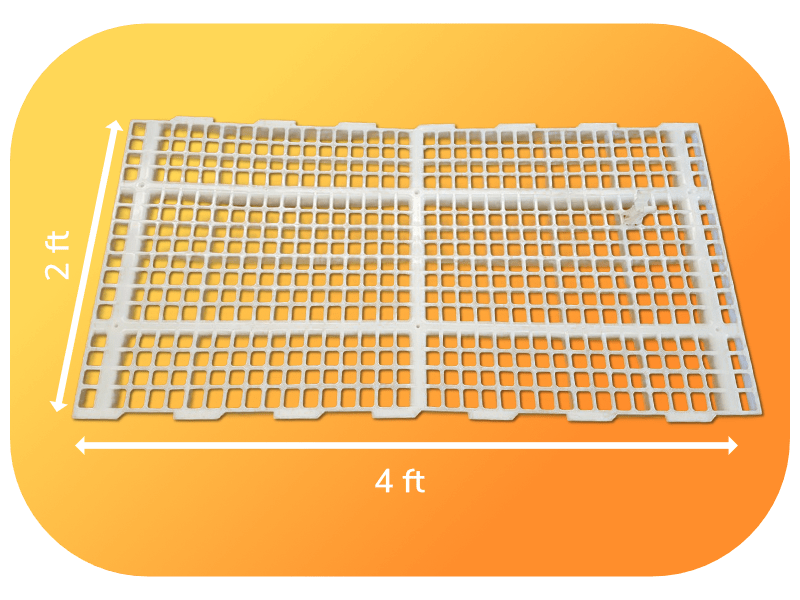

The slat measures 2’ x 4’ and has large 1” square hole openings with a specially designed non-porous surface; this allows for easy manure passage which assists with the prevention of manure build-up and bacteria. This provides a more sanitary environment for the bird and slat eggs when compared with wooden slats.

Matt, a 3rd generation egg producer from Pennsylvania stated, “I’ve been working in egg gathering all my life, and these are the cleanest eggs ever. These eggs are even better than the one’s from my grandpa’s hand collection nest.”

Slats shown after 2 months of use.

Another important feature is that the layers/breeders have a comfortable footing due to the unique design which means a reduction of foot problems and breast blisters.

Engineering

The Sani-Slat’s heavy duty design is rated for up to 250lbs ( 113.4Kg) of static weight per ¼ section of slat in the fully attached/fastened state with both ends and center support. This is due to the reinforced design which offers stronger support both length and cross-ways. The design allows you to install the slats with fewer supports with little or no sag. The screw holes have been reinforced for quick installation to frames.

( Please note users should not run or jump on slats. Improper use would void any warranty or guarantee).

Additional INFO

The overlapping tabs are designed for easy assembly for either wood or metal support systems. Due to the special design of this slat, it requires fewer screws to be used during assembly. This means you will save both on installation time and cost.

The Sani Slat should be stored out of direct sunlight, which can shorten the life of the product.

Leave stretch wrap on pallets until you are ready to install them.

Exposure to outside elements for extended periods of time may also cause damage to the product and void warranties.

Exposure to extreme heat or cold will cause the plastic to expand and contract. Be sure to place in the building with a minimum temperature of 40 degree F (5 degree C) for 24 hours before installing. This temperature should be maintained during the installation.

Please take care in transporting plastic slats. Do not expose the slats to excessive force such as impacts.

Workers should take care to walk on the slats where there are wood or metal frame supports present.

Replace any broken slats immediately.